DAIWA 24 Steez SV TW 100XHL

Overview

STEEZ baitcasting reels are available in spool diameters in 2mm increments.

φ28mm (AIR) φ30mm (CT) φ34mm (LIMITED・AⅡ) φ36mm (HLC)

The Versatile fills the φ32mm hole that has been in the middle for a long time.

The masterpiece that completes the picture of the next generation baitcasting strategy is the third generation STEEZ SV TW with a φ32mm SV BOOST spool.

This third generation does not have a zero adjuster (old mechanical brake). At the time of the second generation 16STEEZ, DAIWA reels already completed brake adjustment only with the MAGFORCE dial. And the third generation has completely removed the mechanism that was once called the mechanical brake and has been reborn with a completely new sub-brake-less structure.

The HYPERDRIVE DESIGN, which controls "winding and durability", is installed in the high-rigidity and compact housing. Casting performance has also been greatly improved, with the G1 duralumin φ32mm SV BOOST spool, TWS, and sub-brakeless mechanisms conforming to the ULTIMATECASTING DESIGN, the "casting design concept" that DAIWA has pursued for many years and finally completed.

HYPERDRIVE DESIGN

The next-generation design concept for bait (double-axis) reels, which significantly improves the standard of all basic performance with the aim of maintaining high initial performance for a long time. The Hyper Drive Design is composed of up to four technologies. Hyper Double Support, which requires the Hyper Drive Digigear to maintain smooth rotation for a long time and assists the gear drive to provide strong and light winding. Hyper Armed Housing, which strongly supports the internal structure and is resistant to bending and distortion. Hyper Tough Clutch with an insulating structure that continues to operate even in harsh locations and drastically reduces adhesion due to salt. The synergistic effect of these technologies continues to provide stable performance in any field.

HYPER ARMED HOUSING (FULL METAL)

A housing system that firmly supports the internal structure with high rigidity and precision, producing a precise winding feel and power. The use of metal materials for the frame, which is the key, is a prerequisite, and in combination with the side plate and set plate, it makes it possible to continue to demonstrate basic performance for an even longer period of time.

In this series, magnesium is used for the frame and gear side side plate (handle side), and aluminum alloy is used for the dial side set plate, which is die-cast and finished with high-precision machine cutting to provide unwavering rigidity.

TWS (T-WING SYSTEM)

TWS has succeeded in significantly reducing the resistance of the line guide close to the spool, where the spool rotation speed is the highest. By reducing the resistance to the casting distance, not only is the casting distance and controllability improved, but the fall is also faster and backlash is reduced. This has realized the possibility of a new level wind not only when winding, but also when casting.

UTD (Ultimate Tournament Drag)

This is a Daiwa drag system that eliminates the initial bite when the drag first starts working, achieving a smooth drag without stickiness (unevenness), while also providing maximum drag power the more you tighten it.

ULTIMATECASTING DESIGN

Making the cast trajectory you imagine a reality.

To realize the Ultimate Casting Design that DAIWA has been pursuing for many years, it was necessary to gather four elements that greatly affect castability and improve the performance of each to the utmost.

These elements are all DAIWA's unique technologies and concepts, including the electromagnetic induction brake [MAGFORCE + variable inductor rotor], which is a world first from DAIWA, [TWS], [G1 duralumin spool], and [ZERO adjust].

The technological innovations that DAIWA has accumulated, the Ultimate Casting Design that has finally been realized, and its future evolution are all for the purpose of making the cast trajectory that anglers imagine a reality.

ULTIMATECASTING BRAKE

Unchanging superiority. Variable individuality

A completely "non-contact" brake system consisting of an electromagnetic induction brake [MAGFORCE] and a [variable inductor rotor] that enters and exits a magnetic field depending on the rotation speed of the spool, etc. Because it is a non-contact type that does not rely on friction, it is less susceptible to the effects of the usage environment such as submersion, rain, splashes, and humidity, and since the parts do not wear out, its performance lasts semi-permanently. In addition, because the effectiveness of MAGFORCE is stable, the variable inductor rotor can be given individual characteristics such as suitability and versatility for lightweight lures, and ultra-long-distance casting ability with two-stage variable.

ULTIMATECASTING ZERO ADJUST

Zero the hassle of using a sub-brake and the ambiguity of settings

DAIWA has perfected the main brake (MAGFORCE), so there is no need for a sub (mechanical) brake. The zero adjuster, born from the idea of [ZERO adjust], allows you to adjust the spool backlash to zero once, and then you can respond to any situation just by adjusting the mag dial.

ULTIMATECASTING LINE GUIDE

TWS is a unique mechanism that combines the effects of winding and casting.

[TWS] achieves precise winding of the line and an expansion of the resistance-free range when casting at the same time. This mechanism makes the flow of the line released smoother, dramatically improving the long casting performance of DAIWA bait reels. TWS is also effective in preventing "line collision accidents" and backlash that occurred with level winding.

ULTIMATECASTING SPOOL

High-strength, low-inertia spool made with special materials and processing technology

Aluminum alloys are often used for baitcasting reel spools, and the G1 duralumin used by DAIWA is considered to be the strongest and highest grade of these. This material is twice as strong as magnesium and 1.3 times stronger than super duralumin, and when used for spools and designed based on strength, it can achieve overwhelming lightness. However, high processing technology is required to finish G1 duralumin with high precision. In order to utilize the material's rigidity as lightness, it is assumed that it can be designed and processed to be extremely thin.

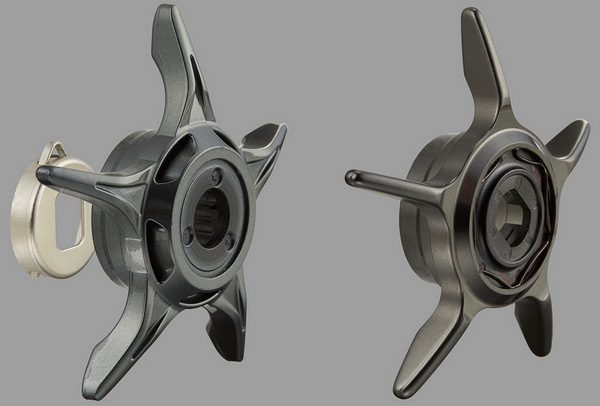

New TWS

In order to reduce line release resistance during casting, that is, to expand the "non-resistance range," we have made some changes to the TWS, which is our only technology.

DAIWA bait casting reels use different TWSs suitable for each spool size. The TWS for this new spool size (left photo) introduces a newly developed taper shape.

Comparing the opening of the new TWS size with and without a taper shape, we have achieved a 27% expansion. In comparison with the TWS installed on the 16STEEZ SV TW (right photo), the opening has been expanded by 16% despite the narrower width. In addition to expanding the non-resistance range, we have maximized line release performance through a synergistic effect with the special surface treatment "DLC."

The results of distance tests with and without a taper shape have shown a maximum increase in distance of 4.9% (with a weight of 7g)

DAIWA continues to refine even its only one technology and pursue a casting feel that makes you want to cast one after another.

G1 duralumin spool

G1 duralumin is a special aluminum alloy that is twice as strong as magnesium and 1.3 times as strong as extra-super duralumin. This ultra-lightweight material with excellent rigidity is the highest grade of lightweight alloy, also used in aircraft structural materials and precision instruments.

To maintain the same strength, it is possible to achieve an overwhelmingly lightweight feel by simply thinning the spool's winding surface without blanking. The high rotation response brought about by the lightness and the unparalleled precision of rotation due to the high rigidity are unmatched.

Zero Shaft

The spool is only supported by the bottom bracket. The shaftless design eliminates excess resistance and provides ideal spool rotation.

In other words, it is the key to a high-output engine that prioritizes casting performance.

Oil injection cap

The zero adjuster has been eliminated due to the sub-brakeless specification. The 24STEEZ SV TW is equipped with an oil injection cap.

The cap can be removed using the included special tool. Removing the cap allows you to oil and maintain the pinion ball bearing.

New star drag shape

In pursuit of maneuverability, a new star drag shape (right) has been installed. It is thinner than the conventional star drag shape (left). Even the ratchet structure has been revised. We paid special attention to even the sound of each click of adjustment. We have achieved a star drag adjustment click sound that resonates with a small, sharp sound.

Drag pull click

In pursuit of high drag performance to catch big fish, we aimed to be the best in its class not only in terms of maximum drag but also in terms of smooth operation that follows the pull of the fish.

It also comes equipped with a drag pull click. It provides a big advantage to anglers by sounding the line system's last-minute attack and defense against a sudden charge by a fish.

HYPER ARMED HOUSING (FULL METAL)

This series uses magnesium for the frame and gear side plate (handle side), and aluminum alloy for the dial side set plate. The die-casting is then finished with high-precision machine cutting to provide unwavering rigidity.

Features

Reel Handle Size | 85 mm |

Reel Hand | Left |

Reel Gear Ratio | 8.5 |

Reel Weight | 160 g |

Reel Spool Depth | PE #1.5 - 120 m ; PE #2 - 100 m |

Reel Bearing # +1 | 12 |

Reel Drag Force | 5 kg |

Reel Winding Length | 85 cm |

Brand | DAIWA |

Be the first to write a review of this product!

![FishingShop.kiwi DAIWA Gekkabijin Type-E Haku [White] 200m #0.35 (1.75lb) DAIWA Gekkabijin Type-E Haku [White] 200m #0.35 (1.75lb)](/wa-data/public/shop/products/25/28/592825/images/352605/352605.200.jpg)

![FishingShop.kiwi DAIWA Gekkabijin Type-E Haku [White] 200m #0.4 (2lb) DAIWA Gekkabijin Type-E Haku [White] 200m #0.4 (2lb)](/wa-data/public/shop/products/26/28/592826/images/352606/352606.200.jpg)

![FishingShop.kiwi DAIWA Gekkabijin Type-E Haku [White] 200m #0.5 (2.5lb) DAIWA Gekkabijin Type-E Haku [White] 200m #0.5 (2.5lb)](/wa-data/public/shop/products/40/57/625740/images/410557/410557.200.jpg)